LED lightbars are a user-friendly yet highly-effective way of illuminating a space. Optimised to deliver both ambient and task lighting, they are ideally suited for use in everything from shelving systems and display cases through to large commercial interiors and pop-up retail spaces.

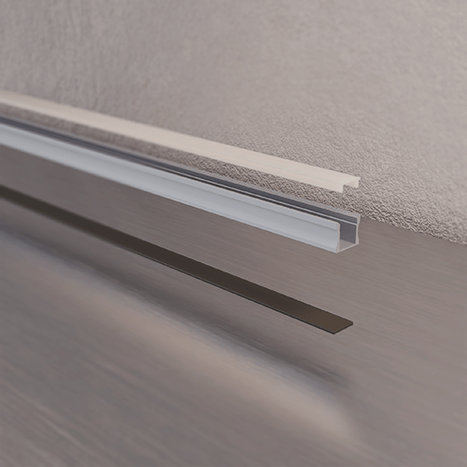

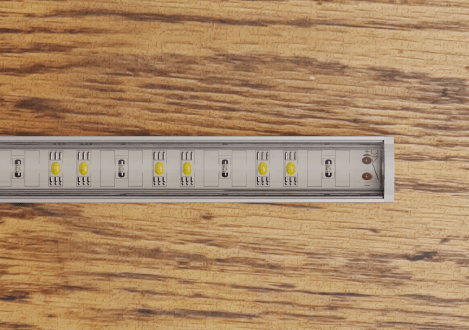

Our lightbars combine energy-efficient LEDs together with a range of different diffusers and slimline aluminium profiles to create lighting elements that perform according to the spatial, functional and aesthetic requirements of a space.

Whether it’s colour temperature, beam angle, lumen output or secondary optics, they can be customised to suit particular displays and showcase products in their best lights.

LED lightbars can be engineered to meet the functional and aesthetic needs of any interior space. Elegant and energy efficient, they are ideal for incorporating illuminated elements into retail displays, art galleries, showrooms, offices, hospitality venues and more.

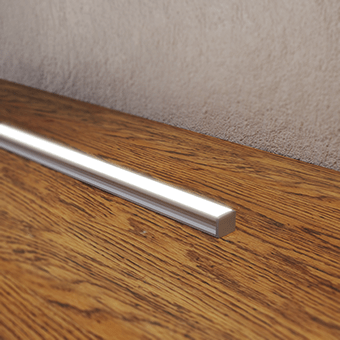

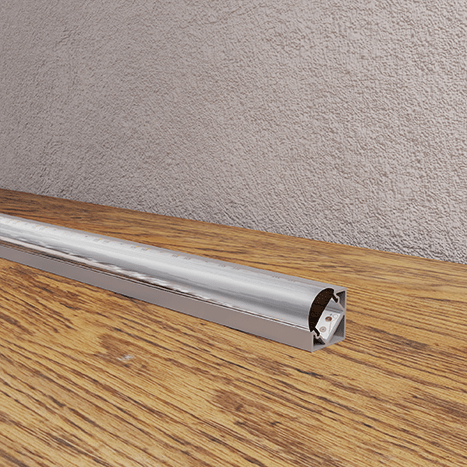

LED lightbars can be mounted directly onto surfaces using a range of different mounting methods. Surface-mounted lightbars protrude from the area onto which they are fixed.

LED lightbars can be recessed into surfaces to create integrated lighting systems that sit completely flush with the area into which they are fixed.

Specially-engineered channels in the aluminium profiles enable lightbars to be suspended above surfaces using cables or rigid posts.

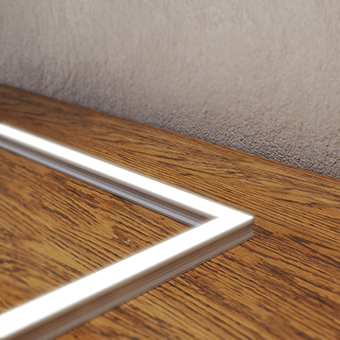

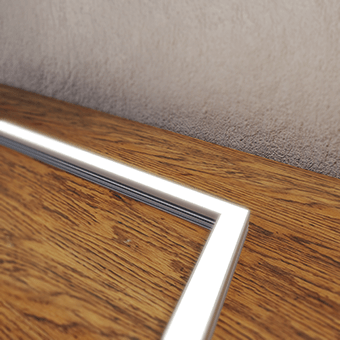

Lightbars can be joined together at right-angles to create linear lighting systems that follow the corners of interior spaces or objects.

Lightbars can be connected together in series to create longer linear lighting systems for larger spaces.

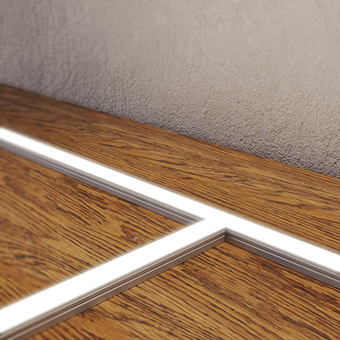

Three individual lightbars can be connected together to form t-shaped lighting fixtures.

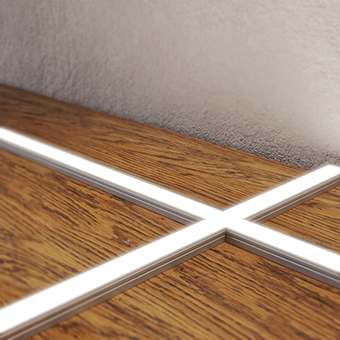

Four lightbars can be connected together to form lighting systems in cross or grid configurations.

To meet user-specific requirements, lightbars can be cut at custom angles so that they can be connected together in configurations that follow the existing interior architecture of a space.

Lightbars can be screwed directly onto surfaces. This is the most suitable fixing method for applications such as under-shelf lighting as it is the most secure.

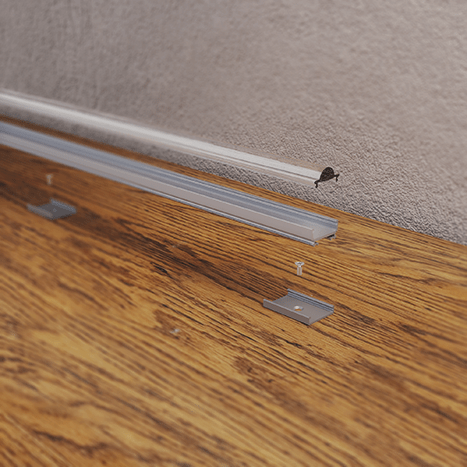

Lightbars can be attached to surfaces using two types of magnetic fixings – plates screw-in plates and self-adhesive tape – making for easy installation and repositioning.

Lightbars can be fixed onto surfaces using high-strength adhesive tape. This is the most versatile mounting method, being suitable for a wide range of different surfaces and materials.

Lightbars can be fixed onto surfaces using clip mounts that are screwed in place. The sluminium profile clicks securely into the channel of the clip.

LED lightbars can be supplied with a number of different diffusers to suit the functional and aesthetic requirements of different environments.

An opaque acrylic diffuser that conceals the internal LED components from view. Opal diffusers are ideal for environments that require a lower-glare option with a soft light transmission.

A semi-opaque acrylic diffuser that conceals some of the internal LED components and PCB from view. Frosted diffusers soften the light emitted whilst allowing for a greater overall light transmission.

A transparent acrylic diffuser that maximises the light transmission of a lightbar to make it as efficient as possible.

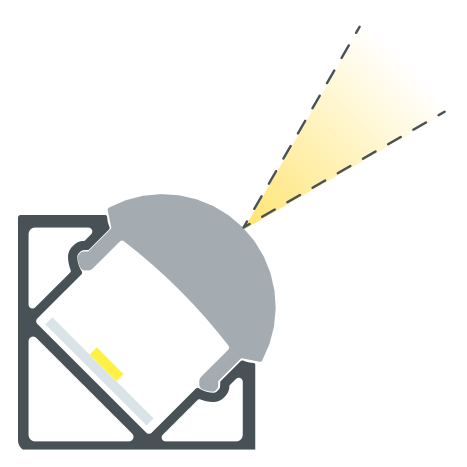

Lenses are used to alter the beam angle of LED components to concentrate the light that is emitted onto a particular product, surface or area of interest.

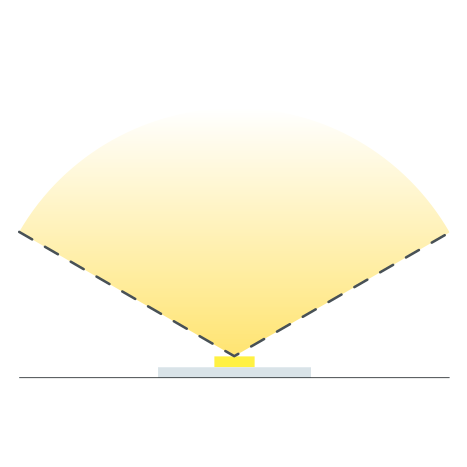

Every light source, be it an LED or a wax candle, has a beam angle. This is the measurement of how the light it emits is distributed within and across a space.

Without the addition of any secondary optics or lenses, LEDs have a standard beam angle of 120°. Smaller beam angles mean that the light emitted by an LED is spread across a narrower area and, as a result, will appear brighter and more intense to the naked eye.

Lightbars can be mounted into specially-engineered aluminium profiles at 45° angles to further re-direct the beam of light onto a particular area or object.

We can help you at any stage of your project. Get in touch with the team today on 0161 655 2100 or [email protected]

Head Office & Manufacturing Facility,

Greenside Way,

Middleton,

Manchester

M24 1SW

For the latest inspiration, news and updates in your inbox, just drop your email in the box below.